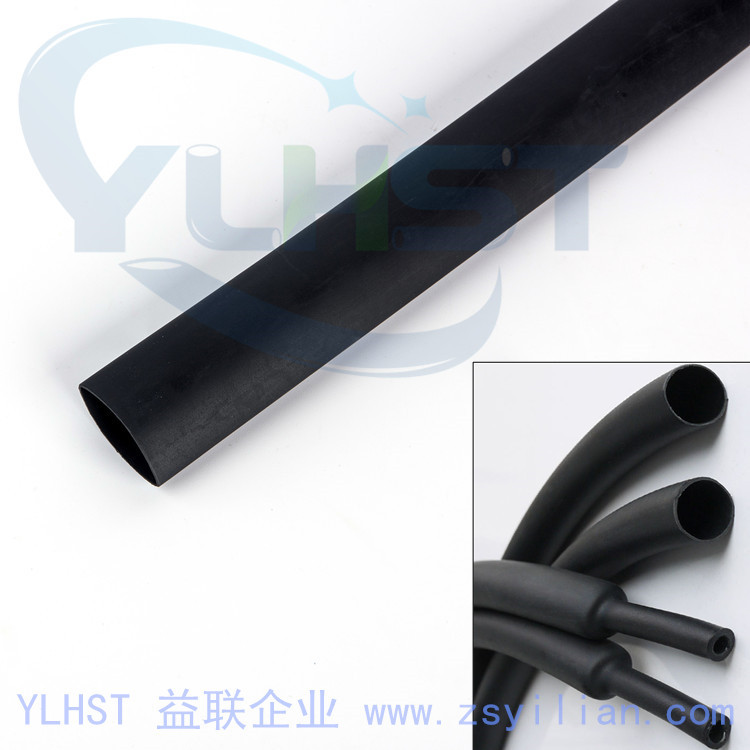

DWG 军标双壁热收缩套管

应用

DWG由优质聚烯烃和热熔胶共挤制造而成,具有优良的物理、化学及电性能,它可将防潮密封,绝缘及机械保护一次性完成,用于需要密封防水防潮胡电线电缆、配线和连接器的绝缘保护。热熔胶与塑料、橡胶、金属有很好胡连接性能,高收缩比能对插头根部进行有效的保护。DWTM符合美军标AMS-DTL-23053/4等级3的要求,可以很好地应用于航天、军工、电子电器、汽车和通讯等很多行业中。

特性

v 高收缩比:3:1,4:1

v 优异的热熔胶和高的收缩比提供了优异的密封

v 不需要移开连接器就可以方便修补损伤的绝缘层

v 热熔胶于塑料、橡胶和金属有很好的粘接性能

v 可选用EVA热熔胶或聚酰胺(PA)热熔胶

v 符合ROHS、REACH等环保规范

颜色

v 标准颜色:黑色

v 其他颜色可定制

操作温度范围

v 连续使用温度范围:-55℃~110℃

v {zd1}起始收缩温度:80℃

v {zd1}wq收缩温度:110℃

符合标准

v SAE AMS-DTL-23053/4,Class 3

v UL224 125℃ 600V

性能指标

|

性能

|

指标要求

|

测试方法

|

典型值

|

|

纵向收缩率

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

抗张强度

|

10.3MPa min

|

ASTM D 638

|

≥12MPa

|

|

断裂伸长率

|

200% min

|

ASTM D 638

|

≥400%

|

|

老化后断裂伸长率

(热老化175℃,168小时)

|

100% min

|

ASTM D 638

|

≥300%

|

|

热冲击

|

无裂纹

|

ASTM D 2671

|

无裂纹

|

|

低温柔软性

(-55℃,4小时)

|

无裂纹

|

ASTM D 2671

|

无裂纹

|

|

绝缘耐压和击穿

|

2500V,60sec,不击穿

|

ASTM D 2671

|

不击穿

|

|

体积电阻率

|

1014Ω•cm min

|

ASTM D 876

|

≥1014Ω•cm

|

|

腐蚀性

|

无腐蚀

|

ASTM D 2671

|

无腐蚀

|

|

阻燃性

|

30秒内自熄

|

UL224

|

通过

|

规格尺寸

|

规格

|

收缩前(mm)

|

收缩后(mm)

|

标准包装(m/条或m/卷)

|

|

内径(min)

|

内径(max)

|

壁厚

|

胶厚

|

|

3:1(inch,mm)

|

|

1/8(3/1)

|

3.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/200

|

|

3/6(4.8/1.6)

|

4.8

|

1.6

|

1.00+0.28

|

0.50

|

1.22/100

|

|

1/4(6/2)

|

6.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

3/8(9/3)

|

9.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/50

|

|

1/2(12/4)

|

12.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

3/4(18/6)

|

18.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

1(24/8)

|

24.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

11/2(39/13)

|

39.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

4:1(mm)

|

|

4/1

|

4.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

8/2

|

8.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/50

|

|

12/3

|

12.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/25

|

|

16/4

|

16.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

24/6

|

24.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

32/8

|

32.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

52/13

|

52.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22

|

壁厚包含胶厚

其他规格尺寸可定制

DWG Army Standard Double Wall Heat Shrinkable

Application

DWG Dual-wall adhesive-lined heat shrinkable tubing is made by co-extrusion of excellent polyolefin compounds and hot-melt adhesive with good physical , chemical and electrical properties. Environmentally seals and protects a wide variety of electrical applications, including back end connector sealing, breakout, and connector-to-cable transitions. High shrink ratio makes it possible to protect cable jackets and connectors. DWTM meets the requirements of military standard AMS-DTL-23053 class 3. It is typically used in the insulation and sealing of aerospace, military, electrical and electrical and electronic components, automotive and communication industry.

Characteristics

v Shrink ratio: 3:1, 4:1

v Good hot-melt adhesive and high expansion ratio to provide good sealing protection.

v Conveniently repair most damaged cable jackets without removing connectors.

v The adhesive bonds to a wide variety of plastics, rubbers, and metals.

v EVA hot melt adhesive or PA adhesive are available.

v ROHS and REACH compliant

Color

v Standard color: Black

v Other colors are available upon request.

Operating Temperature Range

v Operating temperature: -55℃~110℃

v Minimum shrink temperature: 80℃

v Minimum fully recovery temperature: 110℃

Approvals

v SAE AMS-DTL-23053/4,Class 3

v UL224 125℃ 600V

Property

|

Property

|

Requirement

|

Test method

|

Typical data

|

|

Longitudinal shrinkage

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

Tensile strength

|

10.3MPa min

|

ASTM D 638

|

≥12MPa

|

|

Elongation at break

|

200% min

|

ASTM D 638

|

≥400%

|

|

Elongation after aging

(175℃,168hrs)

|

100% min

|

ASTM D 638

|

≥300%

|

|

Heat shock

|

No crack

|

ASTM D 2671

|

No crack

|

|

Low-temperature flexibility(-55℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Dielectric voltage withstand

|

2500V,60sec,no breakdown

|

ASTM D 2671

|

No breakdown

|

|

Volume resistivity

|

1014Ω•cm min

|

ASTM D 876

|

≥1014Ω•cm

|

|

Corrosion

|

No corrosion

|

ASTM D 2671

|

No corrosion

|

|

Flammability

|

Self-extinguishing within 30 seconds

|

UL224

|

Pass

|

Sizes

|

Size

|

As supplied

(mm)

|

After recovered(mm)

|

Standard packing

(m/pc,m/roll)

|

|

Inside diameter

(min)

|

Inside diameter

(max)

|

Wall thickness

|

Adhesive thickness

(nominal)

|

|

3:1(inch,mm)

|

|

1/8(3/1)

|

3.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/200

|

|

3/6(4.8/1.6)

|

4.8

|

1.6

|

1.00+0.28

|

0.50

|

1.22/100

|

|

1/4(6/2)

|

6.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

3/8(9/3)

|

9.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/50

|

|

1/2(12/4)

|

12.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

3/4(18/6)

|

18.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

1(24/8)

|

24.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

11/2(39/13)

|

39.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

4:1(mm)

|

|

4/1

|

4.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

8/2

|

8.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/50

|

|

12/3

|

12.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/25

|

|

16/4

|

16.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

24/6

|

24.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

32/8

|

32.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

52/13

|

52.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22

|

Wall thickness includes adhesive thickness.