进口电动高压调节阀W4F6CP

electric

pressure control valve W4F6CP

品牌:德国沃德WODE

一、概述Overview

德国沃德WODE进口W4F6CP电动高压调节阀又称抗气蚀、低噪声、高压差调节阀、是德国沃德工程技术人员为满足50-600MW火力发电机组配套而开发的新型调节阀,该系列产品经过多次的改进,不继完善,具有新颖性和先进性。

W4F6CP electric pressure control valve, also known as

anti-cavitation and low noise, high-pressure differential regulating valve,

which is the

development of engineering and technical personnel of GER WODE Company To meet the 50-600MW thermal power generating units supporting.The

series has a new and advanced after many improvements and improve.

二、用途Use

安装在电厂锅炉高压差管道上作流量、压力调节用

Installed in

power plant boiler pipe high-pressure differential for regulating flow

or pressure.

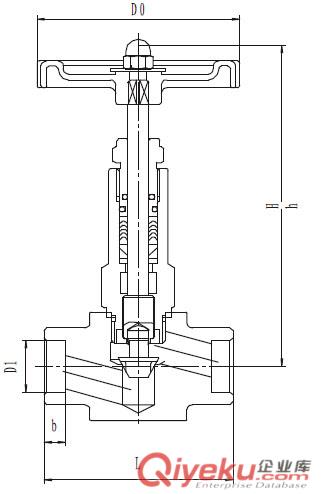

三、结构特征Structure

1、本系列产品采用完合拆装式结构,操作力距小,阀腔内件(包括阀座、

阀芯、节流组件、密封件等)均可从并阀腔取出,维护保养十分方便,阀体不需从管道上割下,可长期使用。

This series

of products together with complete disassembly structure, operation torque is

small, the valve chamber pieces (including the seat,

Valve, throttle assemblies, seals, etc.) can be removed from the chamber

and the valve, maintenance is very convenient, valve body do not have to be cut

from the pipeline,can be long-term use

2、阀芯为柱塞体平衡式结构,操作力距小,调节灵敏高。

Spool is balanced plunger body

structure, operating torque, the adjustment of high sensitivity.

3、节流组件由多孔板集流式节流环与套筒式节流套组成,且配以均流罩,

因此具有小流量高压差无气蚀、大流量、调节性能好,流体排出梳流无噪音的综合特性,wq满足了高压差等苛刻工况的要求,有效地实现了高温、高压差流体的流量调节控制,可调性好,调节精度高。

Throttling

component from the porous flow restrictor plate set ring set with integral

throttle sleeve, and

supported by both flow hood, therefore, no pressure differential with low flow cavitation, the flow,

regulated performance, drain fluid flow without noise comb, fully meet the harsh conditions of high pressure and

poor requirements, effective implementation of the high temperature and

pressure differential control of fluid flow control, adjustable, good

regulation and high precision.

4、节流环可在阀门工作行程的55%之内,实现多级减压节流

Cutting ring can be achieved in

multi-stage vacuum throttle valve work within 55% of stroke.

5、阀芯和阀座密封面堆焊司钛莱硬质合金,抗冲刷、耐蚀。

Core

and valve seat sealing surface is welded titanium Levin Secretary carbide,

anti-erosion and corrosion resistance.

四、阀体Body

型 式: 锻、铸直通式阀体

Type: forging, casting straight-through valve

公称通径:DN10-DN300

DN: 10-300

公称压力: PN25、32Mpa、75Mpa或ANSI 1500 ANSI2500 ANSI4500

Nominal pressure: PN25, 32Mpa ,75Mpaor ANSI 1500 ANSI2500 ANSI4500

连接形式: BW焊接(或用户要求)

Connection Type: BW welding (or user requirements)

材 料: WCB、25、20CrMo

Material: WCB, 25,20 CrMo

上 阀 盖: WCB、25、20CrMo

Bonnet: WCB, 25,20 CrMo

填 料: 柔性石墨或其他

Packing: Flexible graphite or other

介质温度: ≦300°、≦450°

Medium temperature:≦ 300 °, ≦ 450 °

阀内组件:

柱塞平衡式、套筒式

Valve components: balanced piston, sleeve type

流量特性:

等百分比或线性

Flow characteristics: equal percentage or linear

阀座型式: 2Cr13,或其它不锈钢渗氮或焊硬质合金

Seat Type: 2Cr13, or other welding

stainless steel or alloy nitriding

阀芯材料: 2Cr13,或其它不锈钢渗氮或焊硬质合金

Spool material: 2Cr13, or other

welding stainless steel or alloy nitriding

五、执行机构Actuator

型 式:电子式电动带手动执行器等

Type: electronic

electric actuator with manual, etc

阀作用方式:电关或电开式

Mode of action: power off or power open

主 电 源:AC660V、AC380V、AC220V、DC24V

Main Power Source: AC660V、AC380V、AC220V、DC24V

六、阀额定流量系数(KV)值

Rated flow coefficient (KV) values

1—800T/h(按用户提拱的实际工艺参数设计制造

1-800T / h (according to the user's

actual design and manufacturing process parameters)

七、性能Performance

基本误差: ±2.5

Basic error: ± 2.5

回 差: 2%

Hysteresis: 2%

死 区: 2.5%

Dead zone: 2.5%

泄 漏 量: 符合ANSIB16.104-1976IV或VI级

Leakage: meet ANSIB16.104-1976IV or VI level

注:以上尺寸仅供参考,如需更详细的图纸尺寸及资料说明请联系沃德中国代理商。我公司联系电话010-51298906;竭诚欢迎您来电咨询订购。